Automated Storage And Retrieval System Icon

Radioshuttle is a semi automated storage and retrieval system that allows for a maximum use of warehouse space.

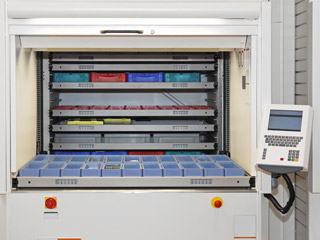

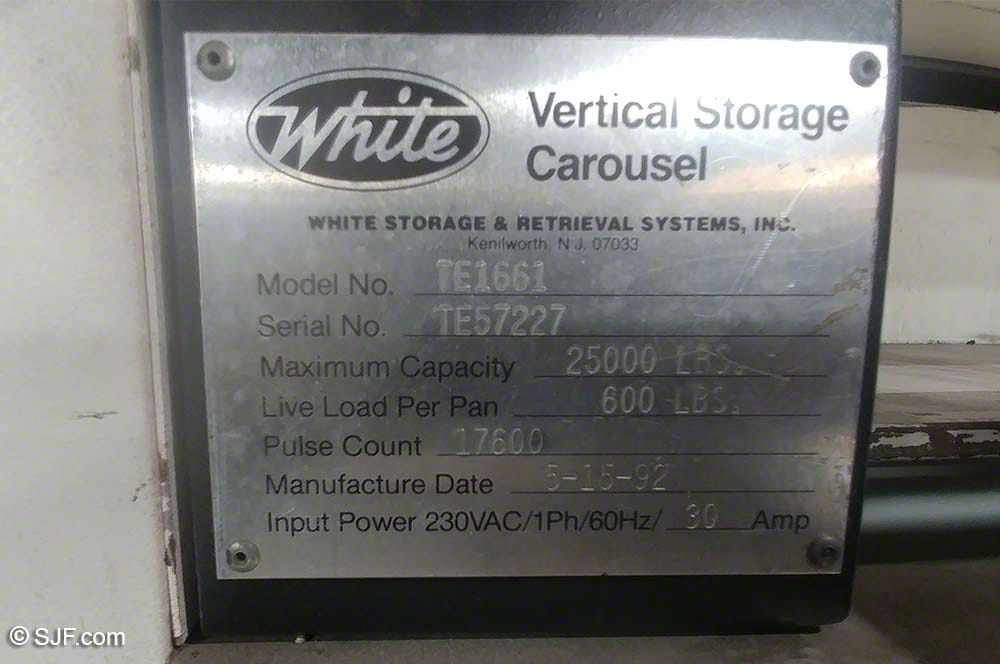

Automated storage and retrieval system icon. One of the most obvious benefits to automated carousel systems is the increased space savings they provide. Automated storage and retrieval systems as rs thrive in applications where high volumes of inventory move in and out of manufacturing or distribution operations. Systems can vary from relatively simple manually controlled point of use storage structures to computer controlled storage and retrieval systems. Most shelving units waste aisle space and don t allow you to fully utilize the ceiling height of your facility.

By eliminating forklift trips down storage aisles and wasted travel time between widely placed racking as rs allow you to run more efficiently and adjust your racking to save. An automated storage retrieval system also referred to as as rs or asrs is a combination of equipment and controls that handles stores and retrieves materials with precision accuracy and speed. Automated storage and retrieval systems as rs offer a faster more efficient way to move goods through your facility using horizontal and vertical storage carousels. Heubel shaw offers warehouse automation solutions ranging from conveyors and cranes to pallet shuttle systems industrial robots automatic forklifts and automated storage and retrieval systems as rs.

Automated storage and retrieval automated storage and retrieval systems as rs provide the benefit of high density storage using a compact footprint. Easily managed with a remote control the radioshuttle pallet shuttle is loaded into storage loads and executes orders to load or unload pallets into a lane. Automated carousels however offer high density storage within a compact footprint. Storing with as rs means accurate real time data is kept on inventory eliminating need for physical inventory inspections and also providing direct access to items at all times.

The systems are customized to the unique needs of your operation delivering the speed and efficiency you need to stay competitive in today s supply chain and distribution center environments. The lanes are fed pallets by lift trucks such as reach trucks or sit down. When correctly applied and effectively utilized automated solutions can save time and money in warehousing and distribution operations. Automated storage and retrieval systems as rs are typically used in applications where.

The warehouse complex and its state of the art automated storage and retrieval system is one of the biggest in the world with capacity for more than 360 000 bins each about the size of a suitcase.